Cement Plant Separator Manufacturers

The separators are known to be widely deployed in cement manufacturing industry especially in the field of grinding circuits. The basic function of these separators is to separate very fine sized particles from the coarse particles. During the separation process, the separated fine particles are collected at one end in the name of finished product whereas the coarse sized particles are further sent back to undergo the grinding process once again. The important trick at this juncture is that the continuous stream of the coarse particles are checked properly for the absence of any fine particles and at the same time, care should be taken to check that the separated fine sized particles are completely free from the coarse sized particles.

High Quality Separators For Any Type & Size Of Cement Plants

A well efficient separator will always prevent the particles from over grinding which on the other hand leads to wastage of energy. The separators can be classified into two types: the dynamic separators and the static separators. The major difference between these two separators is that the static separator doesn’t possess any moving parts and it can be modified only through mechanical modifications.

The static separators can be further classified into 3 sub-categories:

• The V-Separators

• The grit or static separators

• The cyclones

The dynamic separtors can also be classified into 3 sub-categories:

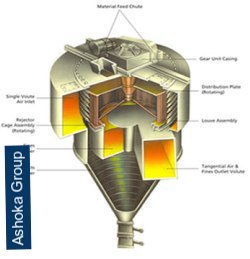

• The cage type separators (this is also called third generation separators or high efficiency separators)

• The cyclone separators (this is otherwise known as second generation separators)

• The turbo separators ( this is also called as first generation separators)

The separators that come with higher efficiency possess the ability to deliver more accurate isolation and hence it decreases the consumption of overall grinding and also mill energy. Separators that belong to the improved version also enhances the capacity of the mill and also increases the quality of the clinker. Because of its efficiency in better size allocation, it can also decrease the kiln energy consumption. The optimization process of these separators has travelled far from the conventional rotary air separator through conventional cyclone air separator to cyclone air separators that are designed with specially designed circumferential screens.

.

For More details about Cement Plant Equipments & Other Mills Projects, Budget, Machines, AMC, Up-gradation etc, Please contact Us @ +91 9811141400 or Send Business Query