As we all know that cement is a material with adhesive and cohesive properties which make it capable of bonding minerals fragments into a compact whole.

For constructional purposes, the meaning of the term “cement” is restricted to the bonding materials used with stones, sand, bricks, building stones, etc.

At Ashoka, We want to explain you that Cement is made from limestone and clay or shale, raw materials are extracted from the quarry crushed to a powder and then mixed or blended in the correct proportions. This mixed raw material is called the kiln feed.

The raw material is heated in a rotary kiln mill, where it reaches a temperature of about 1400 C to 1500 C. In its simplest form, the rotary kiln is a tube up to 200 or 300 meter long and perhaps similar in diameter, with a long flame at one end. The raw kiln feed enters the kiln at the cool end and gradually passes down to the hot end, then falls out of the kiln and cools down. The material formed in the kiln is described as ‘clinker’ and is typically composed of rounded nodules between 1mm and 25mm across.

After cooling, the clinker may be stored temporarily in a clinker store, or it may pass directly to the cement mill. The cement mill grinds the clinker to a fine powder. A small amount of gypsum – a form of calcium sulfate – is normally ground up with the clinker. The gypsum controls the setting properties of the cement when water is added.

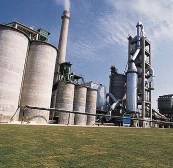

Cement Plant Process

- Portland Cement Plants

- Clinker Cement Plants

- Rotary Kiln Cement Plants

- VSK Cement Plants

Portland cement Plants

Raw materials

• Calcareous material – such as limestone or chalk, as a source of

lime (CaO).

• Clayey material – such as clay or shale (soft clayey stones), as a

source of silica and alumina.

Methods of cement manufacturing

1- Wet process ___ grinding and mixing of the raw materials in the

existence of water.

2- Dry process ___ grinding and mixing of the raw materials in

their dry state.