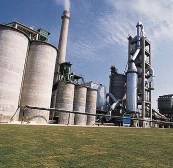

Cement Plant Equipment

Cement Plant Equipment Supplier

We at Ashoka Engineering India’s No. 1 Cement Plant Manufacturer and Equipment suppliers in India offering wide range of Cement Plant equipment under one roof. We are leading heavy industries consulting organization and always working on latest technologies to increase production, durability and environment.

Cement Making is a integrated process that prepares the raw mix, feeds it to the pyro-processing system (kiln), and then grinds the clinker from the kiln system into various cement products. Now finished product is called cement which is stored in large silos on site or bagged for small quantity use. The cement is shipped by truck, rail or barge to customers, or to regional terminals for customer pick-up. Most cement plants have quarries located nearby to supply the limestone and other raw materials.

Cements are a substance that binds other material together. Cements are a binder that hardens and sets independently. Cements are strong building material that can face any natural and artificial environmental effects.

We manufacture and supply all type of Cement Plant Machines and process equipment like Cement Plant Crushers, separators, vertical rollers, kiln and shells, bucket and chain belts etc. The objective of Cement Plants Equipments is to improve the product quality. The raw material used in cement plants are sand, clay, limestone, shale, and iron ore. Cement plants require areas where infrastructure rehabilitation is necessary.

Cement Plant Equipment

Cement manufacturing as a procedure and as a big production has undergone many phases of makeover in current times. Ashoka Cement Plant is one of the big name comes in cement plant manufacturers which holds in-depth province understanding of the cement industry and therefore, is operational to present personalized service which is directed to meet the cement plant manufacturing requirements of customers from cement plants.

Key Services

We provide erection and commissioning consultancy support for all the equipment either supplied by us or purchased from outside vendors. We supervise the trial running of plant with providing training to personnel involved in running of plant.

Basic project consultancy provided by us involves :

- Site selection

- Procurement of required items

- Design consultancy

- Plant erection and commissioning

- Basic feasibility analysis

For more details about Cement Plant Consultation, Projects, Budget, Machines, AMC, Up-gradation etc, Please contact Us @ +91 9811141400 or Send Business Query